INQUIRY:

760-936-2797

AFTER-SALES:

760-936-2797

Reciprocating Sieve Plate Extraction Tower

RET Series

-

Continuous production,

-

Cost-effective,

-

Energy-saving,

-

Environmentally friendly

Overview

The reciprocating sieve plate extraction tower mainly uses reciprocating sieve plates to break up the dispersed phase into small droplets based on the extraction principle, thereby expanding the mass transfer area of the unit dispersed phase liquid and increasing the mass transfer coefficient, thereby achieving the purpose of efficient extraction. Work flow: The light phase and the heavy phase enter the extraction tower from the lower

part of the tower and the upper part of the tower respectively. In the tower, the two phases contact each other in countercurrent. Under the action of the reciprocating sieve plate, a small droplet dispersed phase is formed. Through the countercurrent flow of the dispersed phase and the continuous phase Through contact, one or several components in the material are selectively dissolved in a continuous solvent for mass transfer. Suitable for processing easily emulsifiable systems.

Features

Continuous production

The Yuanhuai extraction tower adopts a continuous production method, which can achieve stable and continuous production and improve production efficiency and product quality.

Small footprint, large processing capacity, and small solvent consumption

Due to its unique structural design, the Yuanhuai extraction tower occupies a relatively small area and can achieve large processing capacity in a limited space and improve production efficiency. In addition, the amount of solvent used in this extraction tower is relatively small, which can reduce production costs and is more in line with environmental protection requirements.

Small pressure drop and high mass transfer efficiency

The extraction tower has a small pressure drop, which can reduce energy consumption and wear of the equipment and extend the service life of the equipment. The mass transfer efficiency is high, which can realize efficient transfer and separation of substances and improve the quality and purity of products.

Support customized services

It can be customized according to customer needs. The materials are generally divided into high borosilicate glass, 304 stainless steel, 316L stainless steel, titanium alloy, etc. The number, spacing and other structures of the sieve plates can be calculated and provided based on the performance of the material and the required degree of separation and purity. Three operating modes are available: fully automatic, semi-automatic, and manual operation.

Glass Reciprocating Sieve Plate Extraction Tower

Glass extraction tower structure:

Yuanhuai YRET series glass reciprocating sieve plate extraction tower is mainly composed of a reciprocating sieve plate extraction tower, light phase tank, heavy phase tank, extraction liquid tank, raffinate liquid phase tank, motor stirring system, inlet and outlet delivery pump, control system, etc.

Model | RET-25 |

|---|---|

Weight(Kg) | 55 |

Dimension(mm) | 900*800*2800 |

Feed pump(optional) | Peristaltic pump*2 |

Buffer tank | 2L*2 |

Heavy phase tank(L) | 10 |

Light phase tank(L) | 10 |

Extraction effective height(mm) | 1500 |

Extraction tower diameter(mm) | 25 |

Processing capacity(L/h) | 10 |

Material | High borosilicate 3.3 |

Stainless Steel Reciprocating Sieve Plate Extraction Tower

Stainless steel extraction tower structure:

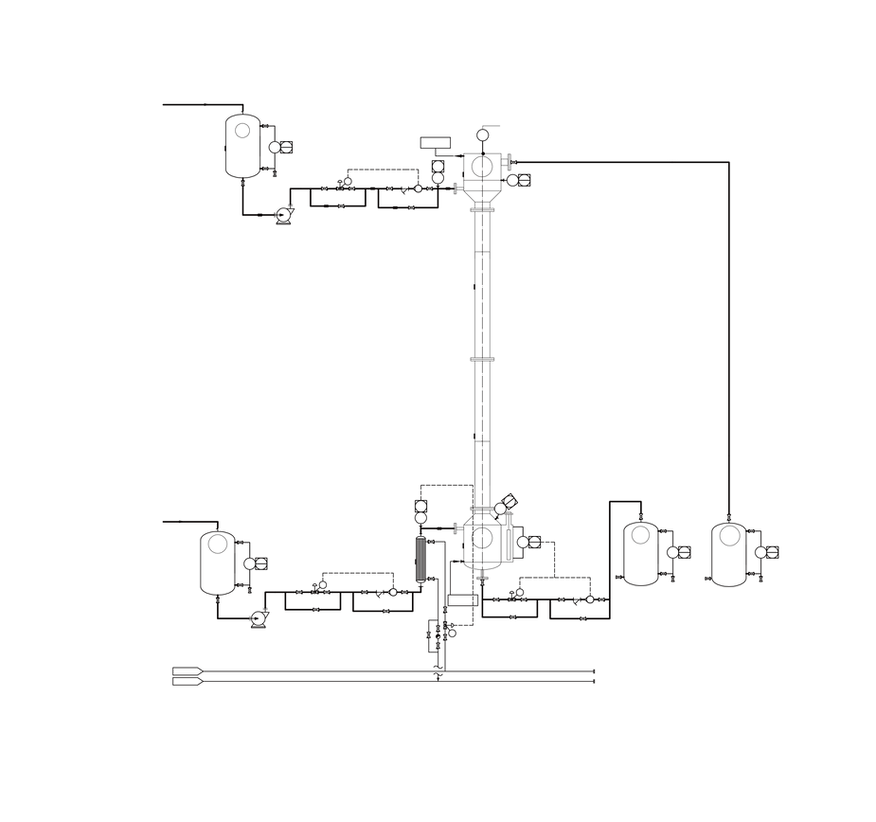

Reciprocating sieve plate extraction tower, light phase inlet and outlet storage tanks, heavy phase inlet and outlet storage tanks, motor stirring system, inlet and outlet transfer pumps, preheating device in front of the tower, various detection instruments and control systems, etc.

Model | YRET-100 | YRET-400 |

|---|---|---|

Inlet and outlet pump | Peristaltic pump | magnetic pump |

Lower enlarged section size | Φ250mm、H600mm | Φ800mm、H1600m |

Expanded section size | Φ250mm、H300mm | Φ800mm、H1000 |

Heavy phase discharge storage tank (L) | 400 | 2400 |

Light phase discharge storage tank (L) | 200 | 6000 |

Heavy phase tank(L) | 100 | 600 |

Light phase tank(L) | 50 | 1500 |

Extraction effective height(mm) | 3000 | 9000 |

Extraction tower diameter(mm) | 100 | 400 |

Total processing capacity of light and heavy phases (L/h) | 150 | 2200 |

Material | SUS 304 | SUS 316L,Lining PTFE |

Typical Applications

The extraction tower is widely used for the separation and purification of liquid mixtures and finds extensive applications in fermentation, bioengineering, and fine chemicals.